Laser Bionic Surfaces

LaBioniCs: Laser Bionic Surfaces

Th is project receives funding in the European Commission’s Horizon 2020 Research Programme under Grant Agreement Number 801250

Objective

LaBionicS aims at both commercializing and industrializing a surface laser processing approach for biomimetic surface texturing developed during LiNaBioFlud project. This approach provides controlled formation functional (micro-/nano- structured) surface textures that mimic skin structures found in different animals and insects (biomimetic surfaces). More specifically the project will use the advanced laser-processing strategies, developed during the LiNaBioFLuid project, based on self-organization of material surface, to mimic the specific topography of the integument of bark bugs, sharks, butterfly wings and moisture harvesting lizards. Our investigations gave strong indications that these nano-features play an important role for the functionalizing surface in engineering applications relevant to Directional Fluid transport, Antibacterial / Antifouling, Antireflectance, Drag reduction, Friction Reduction, Self Cleaning and Water repellency. Beside these main advantageous functionalities, the approach has enormous versatility for modulating the final biomimetic properties and applicability in a real industrial line.

The project will follow an open innovation approach with three main enablers for commercializing and industrializing the technology. There are three main enablers/themes that will facilitate the work of the LaBionicS project that will enable the funneling of different ideas into viable highly potential commercial applications.

Deliverables

| D2.1 | Technology feasibility for commercial applications | Report regarding technology feasibility for different commercial applications. |

| D3.1 | Application- Value chain development report | The deliverable describe the organizational and operational challenges for adopting the biomimetic processing technology |

| D4.1 | Commercialization feasibility study | The deliverable will elaborate on commercialization approach for bio-mimetic surface texturing manufacturing module including descriptions for more appropriate strategies for market positioning, business plan , technical and financial feasibility for industrial applications. |

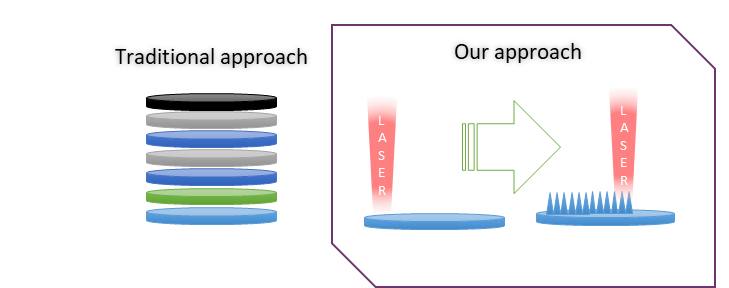

The LaBionicS approach

In comparison with traditional approaches for improving glass surface properties, the proposed technology is following a totally new approach. Traditional approaches for anti-reflective coatings use techniques that deposit multiple thin layers of materials onto glass surfaces under vacuum. Our approach enables precise development of durable functional (micro or nanostructured) surface textures that mimic skin structures found in different insects (biomimetic surfaces). More specifically, we use an advanced laser-processing strategy, developed after many years of research, based on self-organization of material surface, to mimic the specific topography of the integument of bark bugs, wings and cicada wings. The anti-reflective property exist on insect wings due to the presence of arrays (with periodicity in the range of 150–250 nm) of nonreflective nanosized (sub-100 nm size) pillars on both the top and the bottom surface of the wing.

LaBionicS have shown that currently there are two main applications (e.g. Friction reduction and Anti-reflective coatings) that are ready for demonstration. There are clear benefits for using our technology in comparison with traditional approaches. In the other two deliverables, D3.1 and D4.1, we are analyzing further the opportunities from a more commercial perspective.