4D Printing of Biomaterials Scaffolds for Tissue Engineering

Description

The use of additive manufacturing especially fused filament fabrication (FFF) 3D printers have been launched in the last decade as it is easy to use and accessible to everyone. It is a common way to alter the surface of the 3D printed scaffold after is printed with subtractive manufacturing techniques. The most well-known subtractive techniques they used are either with laser (ablation, cutting) or with chemical etching. Although, with laser ablation technique, you could abstract more specific, small designs and use a variety of materials. Until now, they only alter the surface of the scaffolds and at some of them the second layer with changing of the focus. In this way, you could alter the surface of the scaffold with designs more complex and smaller than the resolution of the printer or you could make it more porous [1,2,3,4,5,6]. Moreover, there are many filaments that used for 3D printing but a few of them, mainly polymers used for medical applications. PLA is the most used polymer, PCL, PLGA, PEEK, PET, PLLA and for natural polymer chitosan. In this research project we combined the subtractive and the additive manufacturing to construct 4D scaffolds for tissue engineering.

Specifically, we combined the Ytterbium Picosecond Fiber Laser, wavelength 1060 nm, a galvo scanner and Fused Filament Fabrication (FFF) 3D printer . The use of Galvo is to scan surfaces faster and to have less vibrations (figure 1-3). Moreover, there are many techniques to make 3D scaffolds, but the FFF is a cheap technique, with resolution approximately 100 μm. With combination of laser and galvo, the resolution of laser will be approximately 35μm. So, we can construct structures with laser, with smaller resolution than that of the 3D printer. Furthermore, this combination aims to remove material with specific structure at any layer of the 3D printing structure. This result in making 4D scaffolds with higher resolution, roughness and porosity to make easier the proliferation, attachment and the transfer of nutrients for the cells.

To make the whole setup functional we made some custom parts using FFF technology and other machining methods. A second lead screw, with a stepper to drive it, attached in order to handle the weight of the galvo. Some custom-made 3D printed parts were manufactured to mount the optics in the right place and give a controlled movement of galvo in the desired axis. In order to control all the 3D printers and laser parameters a program written in python was what we built. We can make any desired pattern to our samples either using the 3D printer or the laser. This combination covers the demand for complex scaffolding designs and with an increased resolution compared to 3D printers.

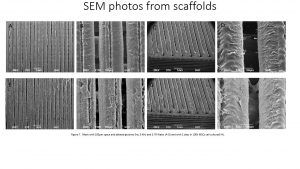

The figures 7 shows the first experimental results from SEM where we ablated only the surface of the mesh with lines of width about 50 um and depth about 67 um. We can observe that the ablated lines are recognizable, and at the center of each strap. Although, there is obvious melting on the surface of the mesh. Then we cultured 100K MSCs for 2 days. We can observe that at all scaffolds the cells proliferated and attached well. Also, the MSCs cells exist between the straps of the mesh, the below layer and inside the ablated designs. This was the first experiment and we wanted to make sure that the cells will be attached and proliferate at the natural PLA filament and the results were positive.

The figure 8 depicts a mesh scaffold with dimensions 10×10 with two different gaps of 0.32 and 0.50 mm and 30 ablated layer by layer holes. We can see that he surfaces of the scaffolds are smooth, and the holes are not all the same size, they are approximately 85 um, analogue to the depth of the hole. Then we cultured 50K MSCs cells for 2, 4 and 8 days. At figure 8 we can observe the cells for 8 days, that proliferated and attached well on the surface, inside and on top of the ablated holes. Also, the MSCs cells grown between the straps of the mesh and at the layer below. At last, we can see a detachment of the cells layer, this is due to the sample preparation and fixation of cells to observe them at SEM.

The figure 9 shows the orthogonal scaffold (10x5mm) with 3 different depths of ablated rectangles (0.15, 0.45 and 0.90 mm) and dimensions of 0.5×1 mm. On the surface it has some gaps at the layers where the laser is occurred. This may be fault of the printer because, the designs are small(10×5) and this may have occurred incoherence in the design or under extrude problem at these layers. Moreover, the ablated rectangles are very clean, they do not have excess material at the sides, but they have a significant roughness, also there have not so much melting around the rectangles. The surface of the main orthogonal is smooth but with splashes of material on the surface. In this case, we can observe if the depth plays a role at the proliferation of the cells. We cultured 50K MSCs cells for 2,4 and 8 days, we can see that the depth indeed plays a role at the cells culture. The 0.15 mm depth seems that has more cells than the other depths. This is appeared from the cells that exist, the cracking on the surface which is due to the fixation of cells, the smother surface of the ablated rectangles and the layer of cells around and above the ablated rectangles.

Bibliography

- Malinauskas M, Rekštyte S, Lukoševičius L, Butkus S, Balčiunas E, Pečiukaityte M, et al. 3D microporous scaffolds manufactured via combination of fused filament fabrication and direct laser writing ablation. Micromachines. 2014;5(4):839–58.

- Malinauskas M, Lukoševičius L, Butkus S, Paipulas D. Femtosecond pulse light filament-assisted microfabrication of biodegradable polylactic acid (PLA) material. J Laser Micro Nanoeng. 2015;10(2):222–8.

- Daskalova A, Ostrowska B, Zhelyazkova A, Święszkowski W, Trifonov A, Declercq H, et al. Improving osteoblasts cells proliferation via femtosecond laser surface modification of 3D-printed poly-ε-caprolactone scaffolds for bone tissue engineering applications. Appl Phys A Mater Sci Process. 2018;124(6):1–15.

- Daskalova A, Bliznakova I, Iordanova E, Yankov G, Grozeva M, Ostrowska B. Preliminary study of surface modification of 3D Poly (ε – Caprolactone) scaffolds by ultrashort laser irradiation. J Phys Conf Ser. 2016;682(1).

- Viertel T, Pabst L, Olbrich M, Ebert R, Horn A, Exner H. Generation of nano-voids inside polylactide using femtosecond laser radiation. Appl Phys A Mater Sci Process [Internet]. 2017;123(12):1–10.

- Rocio Ortiz, Iskander Aurrekoetxea-Rodríguez et al. Laser Surface Microstructuring of a Bio-Resorbable Polymer to Anchor Stem Cells, Control Adipocyte Morphology, and Promote Osteogenesis, Polymers 2018, 10, 1337.

Project Members

Mr. Andreas Lemonis

Ms. Lefki Xaniotaki

Mr. Christos Ntoulias

Dr. Eleftheria Babaliari

Dr. Evi Kavatzikidou

Dr. Emmanuel Stratakis